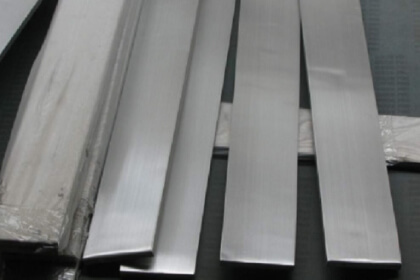

The Stainless Steel Flat Bars are produced using an alloy made from nickel-chromium with minimal additions of copper, manganese, molybdenum, and silicon. The SS Flat Bar’s resistance to corrosion properties are optimal in a variety of atmospheric conditions and many corrosive media. The Stainless Steel 304 Flat Bars undertake tension corrosion cracking above approximately 60 degrees C. SS Flat bar crevices and rough surface finish lead in noticeable corrosion of the metal. With amazing welding properties, the UNS S30400 Stainless Steel Flat Bars have excellent forming characteristics. The Stainless Steel 202 Flat Bars are used for applications under extreme corrosive environments. The Stainless Steel 316 Flat Bars’ machinability specifications are outstanding and can be welded using all traditional welding methods. The SS UNS S31603 Flat Bars also have higher oxidation properties even at cryogenic temperatures.